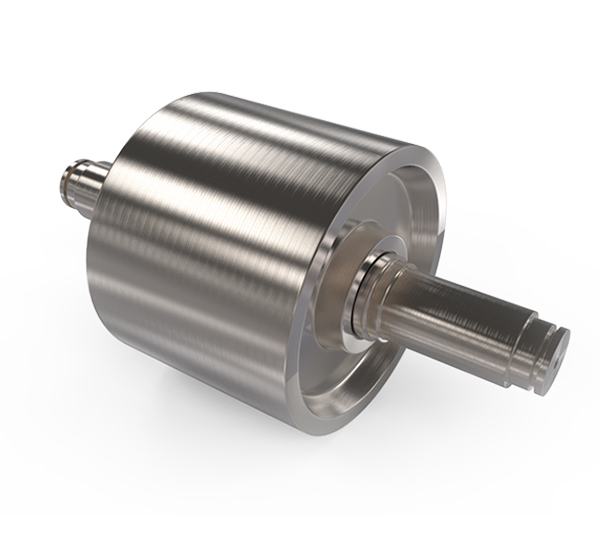

Forging shaft

Type:

Input Size:

Processed Materials:

Detailed Description:

1) Product Name: Forged Shaft, Shaft Forging

2) Material: 4130, 4140, 4317, 4142, 4340, UNS440, 34CrNi3Mo, 25Cr2Ni4MoV, 18CrNiMo5, 30CrMo, 9Cr2Mo, 9Cr2W, 9Cr3Mo, 60CrMoV etc.

3) Max weight: 60ton.

4) MOQ: 20ton.

5) FOB Port: Shanghai Port, China.

6) Delivery Time: 60ton in 30 days.

7) Delivery Condition: Rough Machined, Heat Treated, Fine Machined + EN10204: 3.1B

8) Payment: 30% T/T in advance, Balanced C.A.D.; or 100% L/C

Mill Frequently Used Steel Materials:

1) Wind Power Shaft: 42CrMo4V, 34CrNiMo6; Wind Power Flange: S355NL, C22, 16Mn, 20Mn, 42CrMo, F304.

2) Forged Pipe Fittings: SA106 CL B, SA106 CL C, WB36, 12Cr1MoV, SA335 P11, P12, P22, P91, SA182 Gr.F1, Gr.F5, Gr.F11 CL2, Gr.F12 CL2, Gr.F22 CL3, SA350 Gr.LF1, Gr.LF2,

Gr.LF3.

3) Pressure Vessel Forgings: SA105, SA350 LF2, 16Mn, 20MnMo, 15MnMo, 12Cr2Mo1, 14Cr1Mo, F304, F316, 17-4PH.

4) Shaft Related Forgings: 25CrMo4, 42CrMo4, 40CrNiMo, 34CrNi3Mo, 25Cr2Ni4MoV, 18CrNiMo5, 30CrMo, 4130, 4140.

5) Gear Related Forgings: 35CrMo, 34CrMo4, 4137, 42CrMo, 4140, SCM440, 20CrMnMo, 40CrNiMo, 20CrNi2Mo, 20Cr2Ni4A, 34CrNi3Mo.

6) Copper Forgings: C10100, C10200, C10300, C10700, C12000, C12200.

Forging & Heat Treatment Equipment List

Name & Description | Forging Handling Capacities | Quantity |

6000 Tons Free Forging Press | Max. Single Forging in 45 Tons | 1 |

5000mm Diameter Rolling Forging Machine | Max. Single Forging in 16 Tons | 1 |

800 Tons Free Forging Press | Max. Single Forging in 7.5 Tons | 1 |

60 Tons Forging Handling Operator | Max. Single Forging in 45 Tons | 1 |

10 Tons Forging Handling Operator | Max. Single Forging in 7.5 Tons | 1 |

80 Tons Crane | Max. Single Ingot in 80 Tons | 1 |

60/30 Tons Crane | Max. Single Ingot in 60 Tons | 1 |

30/10 Tons Crane | 30/10 Tons | 5 |

Trolley Heat Furnace | 5000*1500*1200 mm | 3 |

Trolley Heat Furnace | 8000*2000*1600 mm | 3 |

Trolley Heat Furnace | 6500*1500*1200 mm | 4 |

Vertical Heat Furnac | Ø2500*10000 mm | 2 |

Total Forging Equipment Quantity | 24 | |